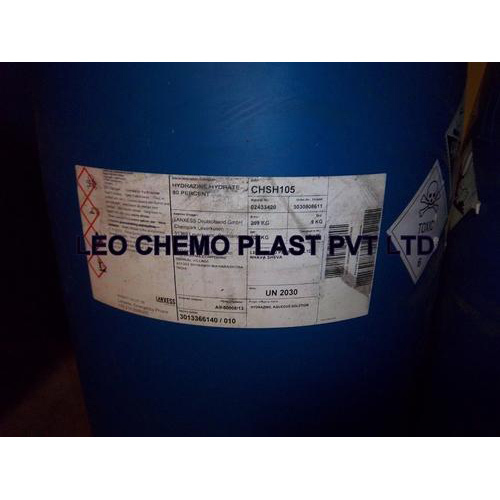

80 Percent Hydrazine Hydrate

80 Percent Hydrazine Hydrate Specification

- Properties

- Highly reactive, strong reducing agent, colorless, fuming liquid, miscible with water

- Ingredients

- Hydrazine Hydrate, Water

- Solubility

- Miscible with water

- Shape

- Liquid

- Molecular Weight

- 50.06 g/mol

- Product Type

- Chemical

- Physical Form

- Liquid

- Smell

- Ammonia-like odor

- Shelf Life

- 1224 months under recommended storage

- Appearance

- Clear, colorless liquid

- EINECS No

- 206-114-9

- Melting Point

- -51C

- Grade

- Industrial

- Structural Formula

- H2NNH2H2O

- Density

- 1.03 Gram per cubic centimeter(g/cm3)

- Molecular Formula

- N2H4H2O

- Storage

- Store in tightly sealed containers, cool, dry, well-ventilated area, away from heat & oxidizers

- CAS No

- 7803-57-8

- Poisonous

- YES

- Purity

- 80%

- Ph Level

- Alkaline (11.211.8)

- Application

- Intermediate in chemical syntheses, boiler water treatment, pharmaceuticals, agrochemicals, polymerization, blowing agents, fuel cells

- HS Code

- 28251090

- Usage

- Used as reducing agent, oxygen scavenger, polymerization catalyst

- Refractive Rate

- 1.418 (20C)

- Auto Ignition Temperature

- 270C

- Toxicity

- Highly toxic by inhalation, skin absorption and ingestion

- Flash Point

- 74C (Closed Cup)

- Packaging

- HDPE drums, IBC tanks, bulk tankers

- Hazard Class

- UN 2030, Class 8 (Corrosive), Class 6.1 (Toxic)

- Vapor Pressure

- 17 mmHg at 25C

- Boiling Point

- 120.1C

- Stability

- Stable under normal conditions, decomposes on exposure to heat

About 80 Percent Hydrazine Hydrate

The offered 80 Percent Hydrazine Hydrate is fuming, and oily liquid. It is colorless liquid and is used as a reducing agent. The chemical compound has got a variety of applications in the industrial as well as commercial facilities. In the treatment of the boiler water, it is used as an oxygen scavenger. Most often, it is used as an auxiliary component for agricultural chemicals and other hydrazine derivatives. Furthermore, our clients can approach us to get this 80 Percent Hydrazine Hydrate from us at the market leading price.

Physical and Chemical Properties

| Physical state and appearance | Liquid. |

|---|---|

| Molecular Weight | 50.06 g/mole |

| Boiling Point | 113.5C (236.3F) |

| Flash point | 72C |

| Melting Point | -51.7C (-61.1F) |

| Specific Gravity | 1 (Water = 1) |

| Vapor Density | 1.1 (Air = 1) |

| Dispersion Properties | See solubility in water, methanol |

| Solubility | Easily soluble in cold water, hot water. Soluble in methanol. Insoluble in diethyl ether |

| N2H4*HO % | 79.7 80.7 |

| NH % | 51 51.6 |

| CI Mg/kg | <=12 |

| SO Mg/kg | <= 1 |

| Fe Mg/kg | <= 0.4 |

Highly Reactive Industrial Chemical

Recognized for its strong reducing properties, Hydrazine Hydrate 80% is a pivotal intermediate in numerous industrial processes. Its colorless, clear appearance and miscibility with water make it easy to integrate into chemical syntheses, boiler water treatment, pharmaceuticals, agrochemicals, and as a catalyst in polymerization.

Strict Safety and Storage Protocols Required

Due to extreme toxicity and corrosiveness, only trained personnel should handle Hydrazine Hydrate. Storage should be in tightly sealed, clearly labeled containers, kept cool, dry, and away from heat and oxidizing substances. Proper containment and ventilation are essential to maintain stability and safety during storage and transport.

Diverse Applications Across Industries

This compound is essential in many sectors for its reducing and catalytic properties. Whether used in fuel cells, as a blowing agent, or in pharmaceutical synthesis, Hydrazine Hydrate 80% offers significant functionality in various high-value manufacturing processes, making it an indispensable industrial reagent.

FAQs of 80 Percent Hydrazine Hydrate:

Q: How is 80 Percent Hydrazine Hydrate typically used in industry?

A: It is commonly employed as a strong reducing agent, oxygen scavenger, and polymerization catalyst. Main applications include boiler water treatment, chemical synthesis, pharmaceutical production, agrochemical formulations, and manufacturing blowing agents and fuel cells.Q: What are the safety precautions for handling this product?

A: Due to its high toxicity and corrosiveness, always handle Hydrazine Hydrate with personal protective equipment (PPE) such as gloves, goggles, and respirators. Ensure adequate ventilation, avoid skin and eye contact, and never inhale vapors. Only trained personnel should manage this substance.Q: Where should Hydrazine Hydrate 80% be stored for maximum stability?

A: Store it in tightly sealed HDPE drums, IBC tanks, or bulk tankers within a cool, dry, and well-ventilated area, away from heat sources and oxidizing agents. Following these recommendations helps maintain stability and minimizes risk of decomposition or accidental exposure.Q: What steps should be taken in the event of accidental exposure to Hydrazine Hydrate?

A: Immediately move to fresh air if inhaled. For skin or eye contact, flush thoroughly with water for at least 15 minutes. Seek medical attention right away, as this chemical is highly toxic and can cause serious harm even at low exposures.Q: What are the storage and shelf life requirements for this chemical?

A: Hydrazine Hydrate 80% should be stored in containers that are tightly closed and made from suitable materials like HDPE. Under recommended storage conditionscool, dry, and well-ventilatedthe shelf life ranges from 12 to 24 months.Q: What benefits does Hydrazine Hydrate 80% provide in boiler water treatment?

A: As an effective oxygen scavenger, it prevents corrosion and scale buildup inside boilers. This protection prolongs equipment life, improves operational efficiency, and reduces maintenance costs in industrial boiler systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Inorganic Compound Category

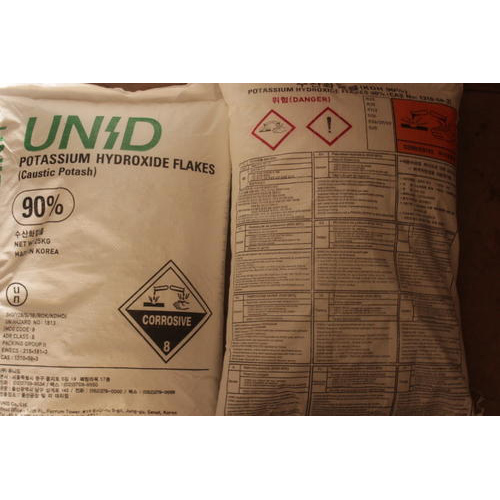

Caustic Potash

Storage : Other, Store in tightly sealed containers, away from moisture, acids, and CO2

CAS No : 1310583

Application : Other , Detergents, soaps, fertilizers, dyes, batteries, chemical manufacturing

HS Code : 28152000

Purity : Minimum 90% KOH (commonly 9095%)

Ph Level : ~14 (1% solution)

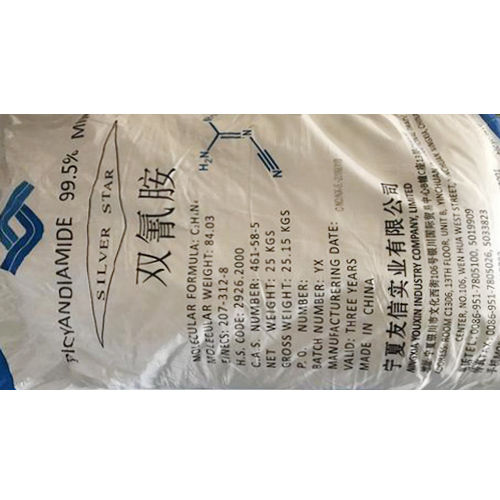

Dicyandiamide

Storage : Other, Store in a cool dry place away from moisture and oxidizing agents

CAS No : 461585

Application : Other , Used in the production of melamine fireproofing agents fertilizers and as a curing agent for epoxy resins

HS Code : 29269070

Purity : 99.5% min

Ph Level : Neutral (approx. 7)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS